SensorTack Gel

A Revolutionary New Technology

Later-generation rain/light sensors use a silicone gel pad that can not be re-used following a windshield replacement because the gel pad surface is often damaged upon removal. Our SensorTack® 1 & 2 Gels are revolutionary products designed to allow the damaged gel pad to be rebuilt, so the original rain sensor is able to be reattached to the windshield in a matter of minutes. In combination with the SensorTack® box, the SensorTack® 1 & 2 Gels can also be processed in mobile situations up to 5°F (-15°C) ambient temperature.

SensorTack® 1 is a transparent (clear) silicone gel used to create round rain sensor pads. Most round rain sensor gel pads can easily be rebuilt with SensorTack® 1 Gel, eliminating the need to purchase an expensive new sensor. This two-component silicone gel is cost-effective, quick and easy to apply, and the old sensor can be reattached to the windscreen in just a few minutes

Part: GGS 901 GEL

SensorTack® 2 is a translucent (milky) silicone gel used to create rectangular rain sensor pads. Most rectangular gel pads can easily be rebuilt with SensorTack® 2 Gel, eliminating the need to purchase an expensive new sensor. This two-component silicone gel is cost-effective, quick and easy to apply, and the old sensor can be reattached to the windscreen in just a few minutes.

Part: GGS 902 GEL

Two Convenient Systems for Rain/Light Sensor Repair

Advantages of SensorTack 1 & 2 Gels

- No Need to Purchase Expensive New Gel Sensors

- Applicable to all Relevant Vehicle Models

- Easy Handling

- Easy Application

- Very Short Cure Time

- Highly Transparent (Clear)

- Constant Material Properties Between -40°F and +356°F

- No Gas Emission During Cure

- Stable and Will Not Shrink

- No Toxic or Irritating Substances

Application Instructions of SensorTack 1 & 2 Gels:

- Remove Rain/Light Sensor from Windshield

- Remove Control Unit

- Clean the Sensor Surface by Completely Removing Old Gel

- Place Sensor on Level Surface (Such as Sensor Tack Heating Box)

- Remove Cap from Syringe

- Attach Mixer Jet to Syringe and Lock in Position

- Attach Slider to Syringe

- Apply Gel to the Clean Optical Surface

- Leave to Cure for a Few Minutes on a Level Surface

- Sensor Can Now be Reattached to the Glass

SensorTack Accessories

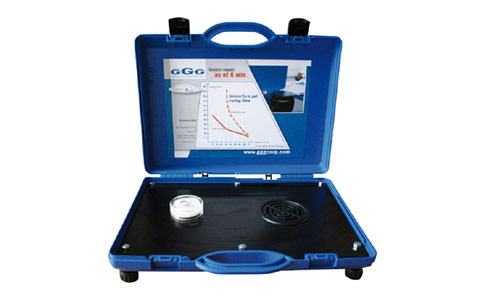

GGG Part: GGS Heat Box

Description: SensorTack Heating Box

Product Information: Heater box for GGS 901 GEL

GGG Part: GGS Heat Box2

Description: SensorTack Heating Box

Product Information: Heater box for GGS 901 GEL and GGS 902 GEL

GGG Part: GGG Mould A

Description: Mould A

Product Information: For the repair of square gel sensors that are 57 x 40 mm. Gel pads can easily be rebuilt with SensorTack 2 Gel and this refill mould.

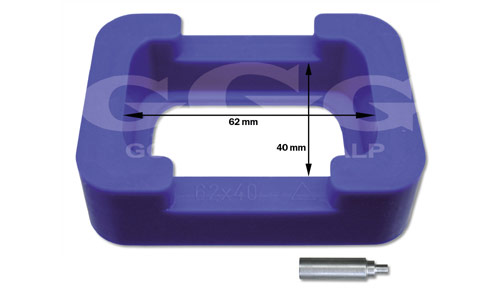

GGG Part: GGG Mould B

Description: Mould B

Product Information: For the repair of square gel sensors that are 62 x 40 mm. Gel pads can easily be rebuilt with SensorTack 2 Gel and this refill mould.

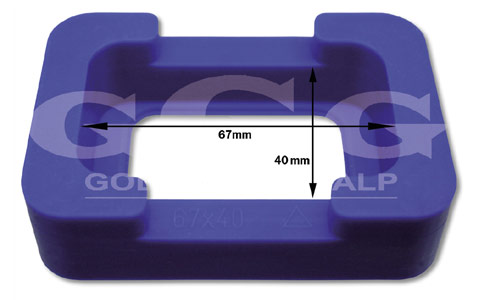

GGG Part: GGG Mould C

Description: Mould C

Product Information: For the repair of square gel sensors that are 67 x 40 mm. Gel pads can easily be rebuilt with SensorTack 2 Gel and this refill mould.

GGG Part: GGG Release

Description: Release Agent

Product Information: Mould release agent for use with SensorTack 2 Gel.

GGG Part: GGS 901 Nozzle

Description: Replacement nozzles

Product Information: Smaller sensor units require only 1/3 of total quantity of the SensorTack syringe. Additional mixing nozzles are available so that the SensorTack syringe may be re-sealed for later use (10pcs/bag).

GGG Part: GGS Leverbar

Description: LeverBar

Product Information: Lever bar for removal of lens cover

For More Information About Replacement Products for AGR Installation

Contact Joanne Feibel: jfeibel@gggalp.com